AUTOMATION AND DIGITALIZATION

Calibration of advanced driver assistance systems:

A true sales booster and customer loyalty driver for vehicle workshops!

Until recently science fiction, today already a reality.

The digital transformation is posing major challenges for the automotive industry.

The trend is shifting increasingly towards intelligent and self-driving vehicles.

This increasing complexity, constantly growing quality and safety requirements, as well as the need for fast and intelligent solutions, are presenting manufacturers and workshops with ever new challenges that only true #VEHICLEEXPERTEERS can master.

Approximately 95% of all traffic accidents can be attributed to human error (autozeitung, 2023). With increasing traffic and the growing need for road safety at the same time, vehicle automatization has become indispensable. Modern vehicles are already equipped with a large number of sensors and cameras to ensure safety on the road. The EU has also recognized the significance of driver assistance technologies and has issued a regulation that makes certain advanced driver assistance systems (ADAS) mandatory in all newly developed vehicles as of 2022. All new vehicle registrations must be equipped with certain ADAS as standard as of 2024. "Vision Zero" aims to virtually eliminate road fatalities in the EU by 2050 (EU Commission, 2022). This means that more than 25,000 human lives are to be saved from fatal accidents and 140,000 from serious injuries by 2038 (bußgeldkatalog, 2023).

How does this development affect vehicle workshops?

Especially in the areas of vehicle diagnostics and calibration of ADAS, the automation trend plays a key role in ensuring safety and a comfortable driving experience. In recent years, many workshops have missed the opportunity to upgrade accordingly and prepare for the autonomization of vehicles. The main concerns of workshops lie primarily in the area of resources, both in terms of costs and manpower.

Is the investment really worth it?

Does the workshop have the necessary know-how?

Calibrating and cashing in: An investment that pays off!

The increasing requirements of car manufacturers for the calibration of advanced driver assistance systems are forcing vehicle workshops to invest in additional equipment. This is why workshops need to expand their portfolio, if they want to continue to retain their customers and generate sales in the long term. This makes it all the more important for workshops to have the right hardware and software for calibration, diagnostics, maintenance and repair as well as the necessary expertise.

With the calibration system WOW! ACS cars, the testing and correct adjustment of driver assistance systems of all relevant vehicle brands is done in no time. Together with the DIALOOQ hardware and software solutions, ACS cars offers the ideal solution for the demanding daily workshop business. Thanks to in-house development, new functions are added and the vehicle and model portfolio is constantly expanding with each diagnostic software update. Of course, we are also at your side with personal consultation and on-site training.

Workshops with the necessary equipment and know-how can establish themselves as reliable partners and retain customers in the long term, instead of referring them to other workshops and suffering a loss of sales as a result.

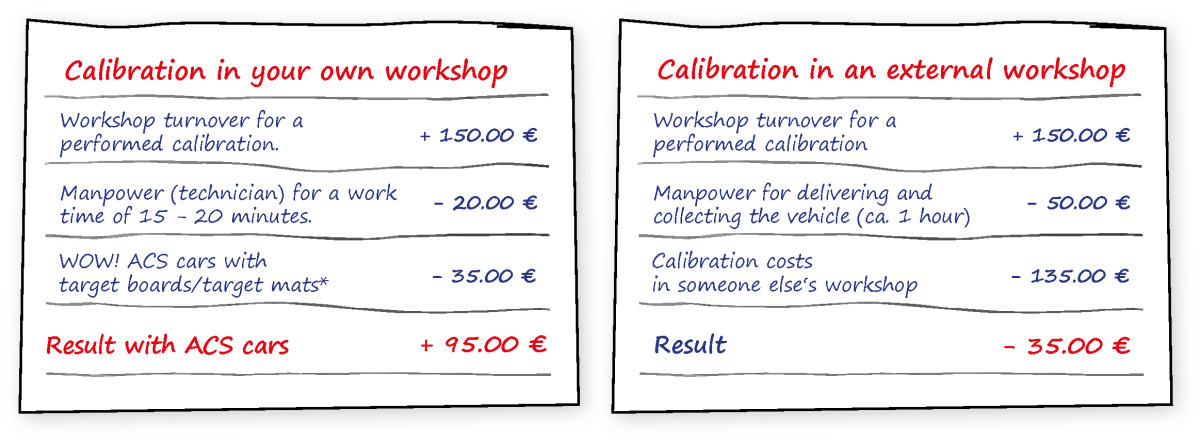

For a calibration after replacing the windshield on an Audi A3. Time required for calibration is 1 hour, according to the manufacturer.

*At 5 calibrations per month, with a depreciation period of 2 years for the calibration system WOW! ACS cars.

Precise calibration of vehicle sensors ensures that advanced driver assistance systems function as intended. However, customers and workshops are often not aware of the need for calibration. Manufacturers set mandatory requirements for proper and correct repair for workshops. This means that workshops may be liable if calibration is either not carried out or carried out incorrectly or if no proof is provided.

Calibration must be carried out not only after an accident, but also when replacing a windshield or a component. Even in the event of minor rear-end damage, it must be checked whether the assistance systems are affected and whether the appropriate adjustments need to be made.

Complex systems only remain complex if you don't know the right people to contact. Würth and WOW! offer you flexible tools, the right work materials and further training in the field of automotive glass repair and bodywork to help you become a vehicle expert.

We offer you a comprehensive calibration and repair concept from WOW! and Würth so that you are prepared for the autonomous future.

* Availability of products and services may vary per country. Get into contact with your Würth national subsidiary for information about the scope of services.